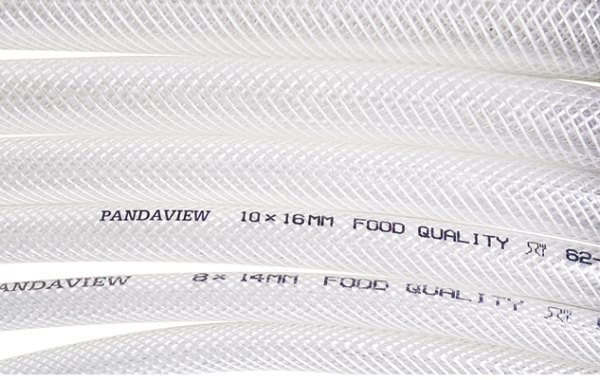

MAQUINA PRODUCTORA DE MANGUERA TRENZADA

Especificación:

|

A. working environment |

|

|

1. working location: |

lndoor |

|

2.humidity: |

85% no condensation |

|

3. temperature: |

0~40°℃ |

|

B.usage condition |

|

|

1.motor drive: |

3phrase 380v (-10%,+5%)50Hz |

|

2.Cooling water: |

ressure≥0.4MPa 2m3/h |

|

C.General Information |

|

|

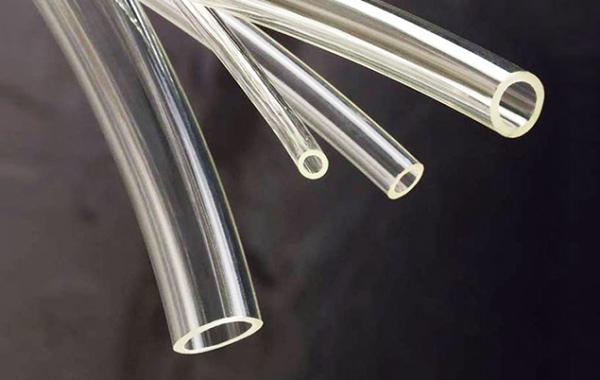

1.Hose production range: |

6-50mm(6,8,10,12,16,19,25,32,50) |

|

2.Material: |

PVC soft granule, yarn |

|

3.Total weight: |

~6000kg |

|

4. Whole line length: |

~15 meters |

|

5.Hose max output: |

50-80kg/h, according to the hose size |

|

6.lnstallation power: |

-78kw |

|

7.Powerconsumption: |

-60kw |

|

D.Summary |

|

|

1.SJ65x30 single screw extruder: |

2sets |

|

2.Control cabinet: |

2sets |

|

3.hose extrusion head: |

2sets |

|

4.Hose spray cooling water tank(2.4m): |

2sets |

|

5.Fiber Knitting Crochet machine: |

3set |

|

6.Oven: |

1set |

|

7.Hose haul-off machine: |

2sets |

|

8.Semi-automatic winder: |

1set |

|

9.Hose sealer: |

1set |

|

10.SJ25 marking line extruder: |

3sets |

|

11.drying hopper: |

2 sets |

|

E.Technical data |

|

|

l Extruder name SJ65x30 |

|

|

1 Extruder |

|

|

1.1 Type: |

single screw extruder |

|

1.2 Central height: |

1000mm |

|

1.3 Max extrusion capacity: |

60-70kg/h |

|

2 Screw |

|

|

2.1 Diameter: |

65mm |

|

2.2 L/D: |

30 |

|

2.3 Material of screw: |

38CrMoAlA |

|

2.4 Surface treatment: |

Nitriding processed |

|

2.5 Nitriding thickness: |

0.50-0.70mm |

|

3 Barrel |

|

|

3.1 Material of barrel: |

38CrMoAIA |

|

3.2 Surface treatment: |

Nitriding processed |

|

3.3 Nitriding thickness: |

0.50-0.70mm |

|

3.4 Heating zones: |

3 |

|

3.5 Heating method: |

Cast Aluminum heater |

|

3.6 Heating power: |

9kw |

|

3.7 Cooling mode: |

air fans |

|

3.8 Cooling power: |

0.20kwX3 |

|

4 Speed reducing box |

|

|

4.1 Tank material : |

HT200 |

|

4.2 Gear type: |

Helical gears |

|

4.3 Gear material: |

20CrMnTi, carburized and quenching |

|

4.4 Lubricating system: |

Pressure system |

|

5 Driving motor |

|

|

5.1 Type of motor: |

AC motor |

|

5.2 Motor power: |

18.5kw |

|

5.4 Speed control: |

Frequency conversion |

|

5.5 power source: |

3p*380V*50HZ |

|

6 Automatic feeding and stainless steel hopper device |

|

|

6.1 Type: |

Automatic vacuum feeding |

|

6.2 Max feeding capacity: |

100kg/h/set |

|

6.3 Stainless steel hoppervolume: |

50L |

|

ll Electricity control system |

|

|

1.Temperature control: |

Toky (Japan) |

|

2.lnverter: |

ABB |

|

3.Electricity parts: |

Schneider |

|

II Hose extrusion head |

|

|

1.Quantity: |

5 sets |

|

2.Die material: |

45# steel, forged, chrome-plated surface |

|

3. mould quantity: |

8sets |

|

4.Mould size: |

6,8,10,12,16,19,25,32,38,50mm |

|

5.heating power: |

1.5kw |

|

IV Spray cooling water tank |

|

|

1.Tank length: |

2400mm |

|

2.Material of tank: |

Stainless Steel |

|

V Fiber Knitting Crochet machine |

|

|

1.Qty of Weft Yarn: |

5 Bobbins 10 needles for 6-15mm, 6 bobbins |

|

2.Bobbin inner size: |

12needles for 16-25mm 6 bobbins 24needlesfor 32mm,38mm , 50mm made in Germany dia.300mm |

|

3.Loading yarn weight: |

10kgs(12kg is the max) |

|

4.Yarn transmission type: |

synchronous belt drive |

|

5.Motor power: |

3kw |

|

6. Safety device: |

Mesh Cover |

|

7.Speed: |

2-5m/min |

|

VI oven |

|

|

1. Drying effective length: |

lset |

|

2.Power of the dryer: |

Two sets |

|

VI I Soft hose haul-off machine |

|

|

Haul-off power: |

1set |

|

VIII Semi-automatic winder |

|

|

Winding roller supply |

|